CamelConvey Overhead Conveyor Trolley Wheels: Full Ball vs. Retainer Type

- Share

- Issue Time

- Jan 3,2025

Summary

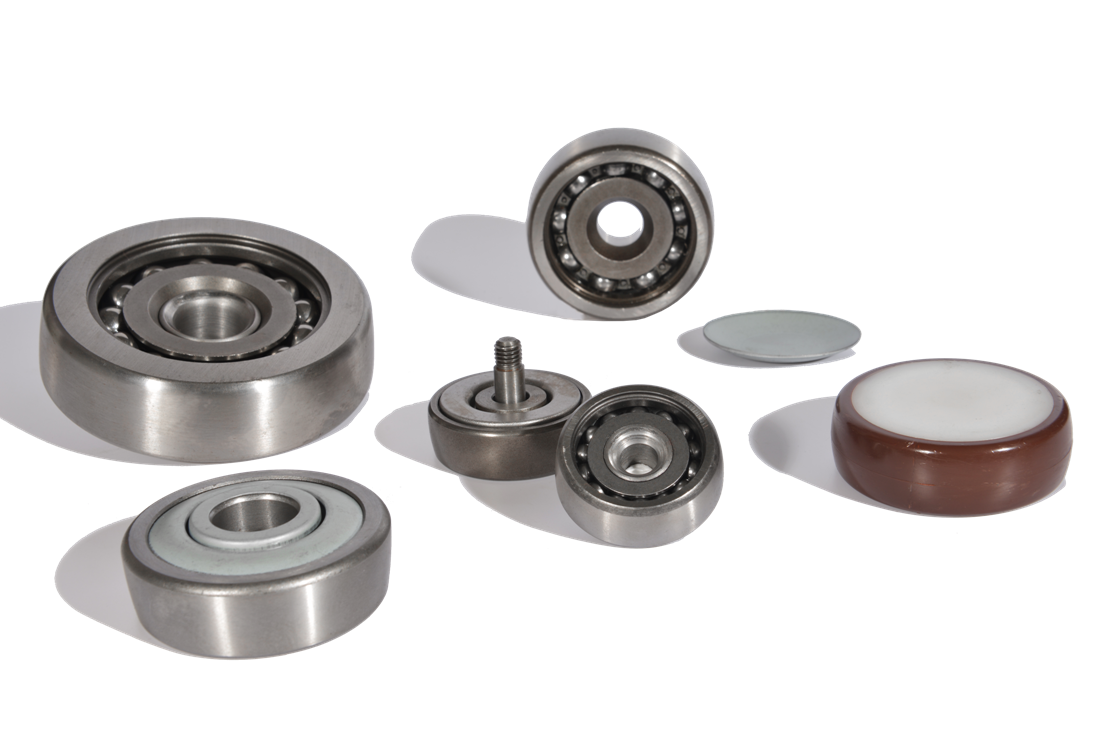

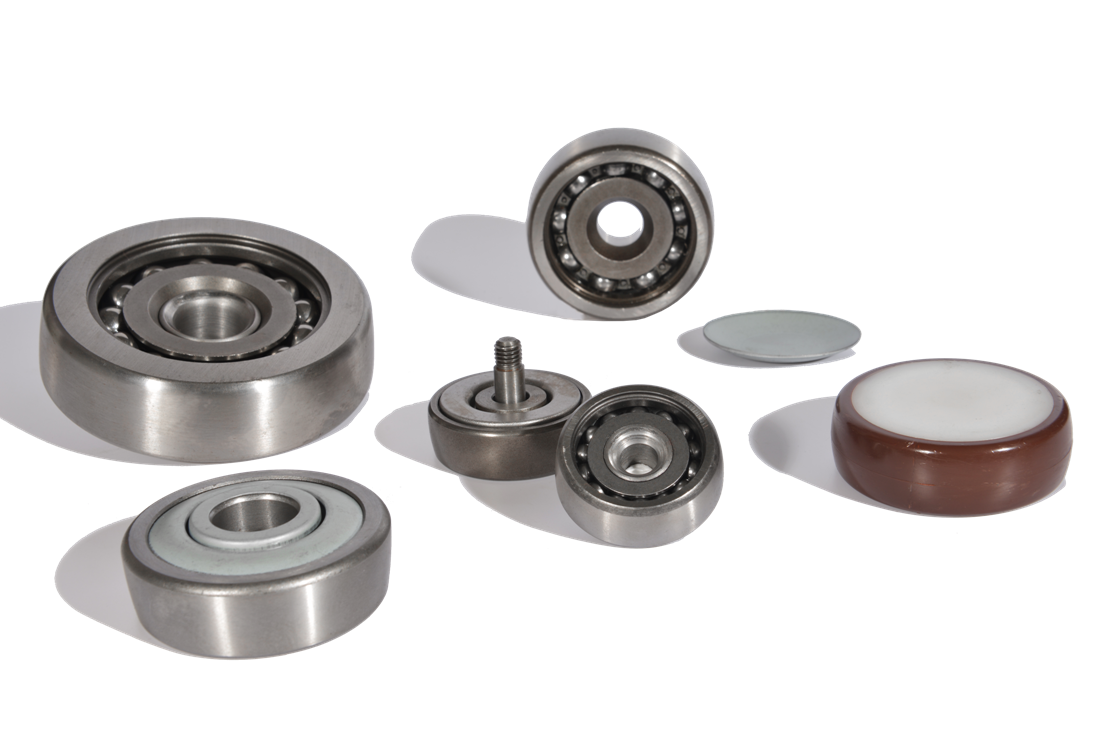

One of our flagship products is the overhead conveyor trolley wheel, which comes in two distinct ball installation types: Full Ball and Retainer Type.

At CamelConvey, we specialize in manufacturing high-quality overhead conveyor components.

One of our flagship products is the overhead conveyor trolley wheel, which comes in two distinct ball installation types: Full Ball and Retainer Type. Both designs offer unique advantages tailored to different industrial applications. In this blog post, we'll delve into the characteristics of each type to help you understand which might be the best fit for your needs.

Features Comparison

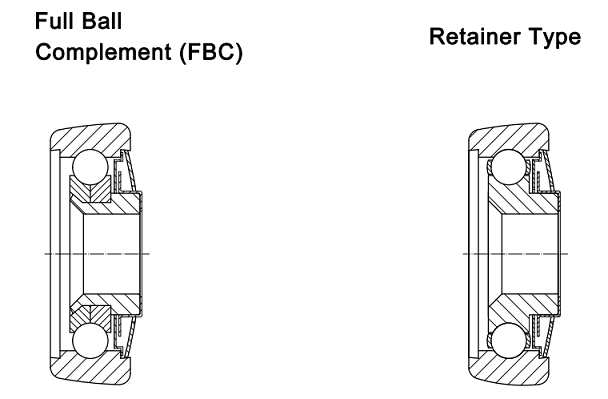

Features | Full Ball Complement (FBC) | Retainer Type |

Energy Consideration | Moderate power requirement due to ball-to-ball sliding contact. | Low power requirement due to low friction design with balls separated by a coined, two-piece steel ball separator. |

Raceway Design | Deep-groove, fully contoured raceways designed to handle heavy, bi-directional radial and thrust loads. Split inner raceway provides deeper ball path and more balls for higher load capacity. Double lock feature ensures the split inner rings do not spread apart. The raceways are case-hardened to Rc 58 min. for maximum shock and wear capability | One-piece, fully contoured inner raceway for continuous radial and thrust loads. The raceways are hardened to Rc 58 min. for optimal performance. |

Internal Fit-Up | Greater clearance for misalignment tolerance and to prevent bearing freeze-up due to contamination and heat expansion. Option for higher temperature applications with special materials or extra clearance. | Normal internal radial fit-up with a ball separator for smooth operation and adequate clearance for misalignment tolerance. |

Heat Capability | Can withstand temperatures up to 500°F (260°C). For applications above 500°F, special internal clearances are recommended. | Suitable for temperatures up to 325°F (162°C). This limit is due to less internal clearance for heat expansion. |

Contamination Tolerance | Capable of handling high contamination levels, both dry and liquid, with optimal performance using triple labyrinth seals. Additional tolerance with contact lip seals. | Suitable for moderate contamination levels. Additional to lerance achieved with contact lip seals. |

Load Capacity | Superior load capacity due to the increased number of balls. ldeal for peak and continuous radial and thrust loads from any direction. The best option for shock and impact loading. Note: In system design, I-Beam is the limiting load factor. | High load capacity, though exceeded by full ball complement wheels. Adequate for most conveyor systems. Note: In system desian, l-Beam is the limiting load factor. |

The quality of overhead conveyor trolley wheels directly impacts the performance and reliability of trolleys, requiring them to meet strict load-bearing and wear-resistance standards. At Camelconvey, we ensure excellence in both full ball type and retainer type by using high-quality raw materials. The inner and outer rings of our rollers undergo heat treatment to enhance their durability. For overhead conveyor trolley wheels with larger outer diameters, we employ advanced salt bath heat treatment, ensuring uniform internal hardness. The hardness of the inner and outer rings reaches a minimum of Rockwell C-58. To ensure smooth ball rotation, the inner and outer grooves are meticulously ground to precision. The balls themselves are crafted from high-grade materials, precision-ground, and hardened to a minimum of Rockwell C-60, delivering superior performance and extended service life.

At CamelConvey, we are committed to providing reliable and durable solutions tailored to meet the needs of our customers. With our overhead conveyor trolley wheels, you can trust in quality that supports the strength and longevity of your systems.