Choosing the Right Conveyor Rollers for Your Business Needs

- Share

- Issue Time

- Aug 21,2024

Summary

The importance of selecting the right type of conveyor rollers based on the specific needs of different industries and applications.

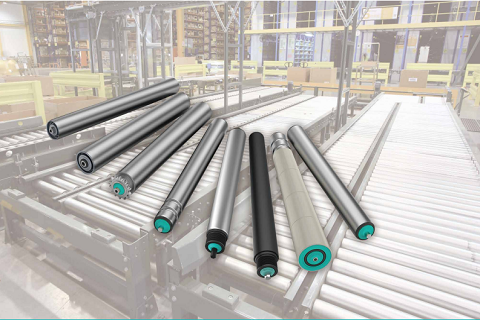

When it comes to optimizing material handling in your warehouse, manufacturing plant, or distribution center, selecting the right conveyor rollers is crucial. Conveyor rollers are integral components of both powered and unpowered conveyor systems, and they significantly impact the efficiency and safety of your operations.

Understanding Your Application Requirements

Different environments demand different types of conveyor rollers. For example, general-purpose steel rollers are cost-effective for light to medium-duty tasks, perfect for warehousing and package handling. On the other hand, if your operations involve frequent washdowns or exposure to corrosive chemicals, corrosion-resistant stainless steel rollers are a better choice. These rollers are ideal for food processing, chemical handling, and pharmaceutical industries, where hygiene and durability are paramount.

Heavy-Duty Tasks Require Robust Solutions

If your operations involve moving heavy items like pallets, drums, or bulk containers, sprocketed heavy-duty rollers are essential. These rollers are designed to handle the rigors of heavy-duty chain-drive systems, offering reliability even in challenging conditions like dirty or oily environments. Their durability and resistance to impact and abrasion make them perfect for high-stress applications.

Consider the Environment and Speed

For high-speed conveying tasks, high-performance steel rollers equipped with precision bearings are ideal. These rollers are not only quieter but also handle higher loads with ease, making them suitable for fast-paced environments like transportation and sorting operations. For more delicate items, cushioned-ride rollers with a smooth plastic covering offer protection against damage while maintaining efficient operation.

Why Material Matters

The material of your conveyor rollers can significantly impact your operations. Lightweight aluminum rollers are easy to move and reconfigure, making them suitable for systems that require frequent adjustments. In contrast, high-durability steel rollers offer higher resistance to wear and tear, making them perfect for demanding applications involving heavy loads.

Conclusion

Selecting the right conveyor rollers involves considering various factors, including the nature of the load, the operating environment, and the specific demands of your conveyor system. By choosing the appropriate rollers, you can enhance the efficiency, safety, and longevity of your material handling systems, ultimately contributing to smoother operations and cost savings.

CamelConvey has advanced manufacturing technology and a professional engineering team to provide customers with customized solutions. If you need help, please contact us. We look forward to working with you!