Why CamelConvey Plastic Ball Bearings Are Your Ideal Choice for Overhead Conveyor Systems?

- Share

- Issue Time

- Nov 19,2024

Summary

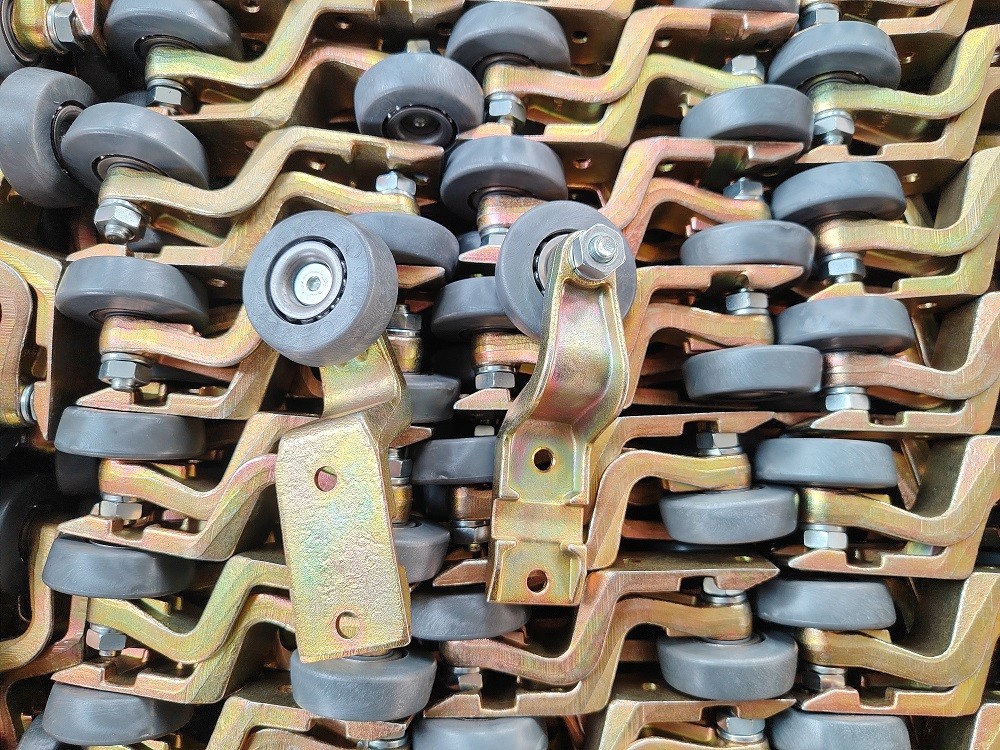

CamelConvey I beam conveyor trolley with plastic bearings are engineered for quiet operation, reducing noise and vibrations significantly compared to metal alternatives.

When it comes to overhead conveyor systems, CamelConvey plastic ball bearings are engineered to be the preferred solution, thanks to their low coefficient of friction, compact design, and suitability for restricted installation spaces. While traditional metal bearings are commonly used for their high load capacity and durability in tough environments, they come with their own set of limitations that CamelConvey bearings are designed to overcome.

Minimize Maintenance, Maximize Efficiency

One significant drawback of metal ball bearings is the need for regular maintenance, particularly relubrication, which is costly, time-consuming, and challenging to perform in hard-to-reach overhead systems. Insufficient lubrication is a leading cause of bearing failure, making it essential to avoid components that require frequent upkeep. CamelConvey's overhead trolley with plastic ball bearings are crafted from a tribologically optimized polymer blend containing solid lubricants. This ensures consistent and effective lubrication throughout the bearing's lifespan, eliminating the need for relubrication and reducing overall maintenance costs.

Cost Savings That Add Up

Switching from metal to CamelConvey plastic ball bearings offers substantial cost savings as well. Our plastic bearings are up to 40% more economical than metal bearings, which is an enormous benefit when outfitting large conveyor systems that may require hundreds or thousands of bearings.

Built to Resist Corrosion, Dust, and Dirt

Corrosion remains a concern with metal ball bearings, particularly in humid or dusty environments where rust and grime can compromise performance and cause failures. CamelConvey plastic ball bearings, however, are not only corrosion-resistant but also repel dirt and dust due to the absence of greased lubrication. Designed for challenging environments, CamelConvey bearings maintain performance in humidity, dirt, and even chemically corrosive conditions, making them ideal for overhead conveyor systems in tough industrial settings.

Quiet, Reliable Performance for a Safer Work Environment

CamelConvey I beam conveyor trolley with plastic bearings are engineered for quiet operation, reducing noise and vibrations significantly compared to metal alternatives. This lower noise level contributes to a safer and more focused work environment, making it easier for employees to communicate and stay alert.

Tailored for Your Unique System Requirements

At CamelConvey, we understand that every conveyor system is unique. That's why we offer custom plastic ball bearing solutions tailored precisely to your application requirements. Whether you need specific technical dimensions or performance characteristics, CamelConvey can provide customized designs based on your technical specifications. And with no order quantity limitations, you can install the perfect solution, no matter the size of your system.

Choose CamelConvey overhead trolley to improve efficiency, reduce costs, and achieve a streamlined, low-maintenance solution for your overhead conveyor system. CamelConvey — where innovation meets reliability.