What types of conveyor rollers are available?

- Share

- Issue Time

- Aug 21,2024

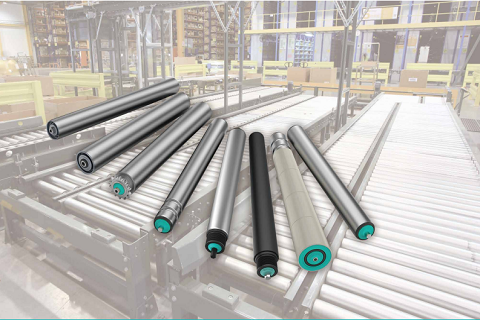

1. General Purpose Steel Rollers:

Suitable for light-duty and medium-duty unpowered conveying tasks in warehousing, package handling, manufacturing, and distribution.

2. Corrosion-Resistant Stainless Steel Rollers:

Ideal for environments with high humidity, corrosive chemicals, or frequent washdowns, such as in food processing or pharmaceutical facilities.

3. Lightweight Aluminum Rollers:

Commonly used in unpowered conveyors where frequent disassembly or reconfiguration is needed.

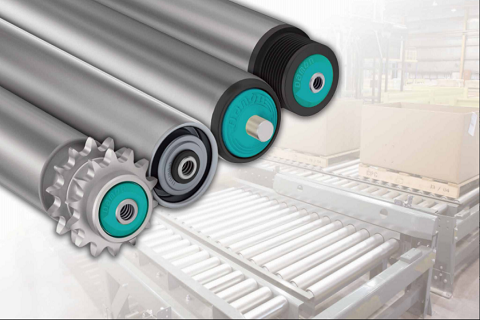

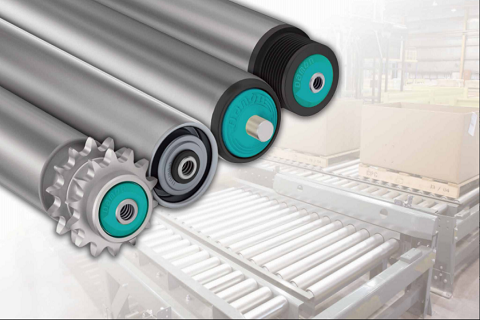

4. Sprocketed Heavy-Duty Rollers:

Designed for heavy-duty chain-drive conveyors to move heavy items like pallets and drums.

5. High-Durability Steel Rollers:

Used for conveying heavy loads with higher resistance to impact, shock, and abrasion.

6. High-Performance Steel Rollers:

Suitable for high-speed conveying tasks with sealed precision bearings for quieter and more efficient operation.

7. Cushioned-Ride High-Performance Rollers:

Used for high-speed conveyors carrying delicate items, featuring a plastic covering for reduced noise and increased traction.

8. Non-Marring Rollers:

Designed with a smooth plastic covering to protect delicate surfaces and reduce noise.