Why Use an Overhead Conveyor System in Industrial Applications?

- Share

- Issue Time

- May 21,2025

An overhead conveyor system is a mechanized track installed above the ground, typically suspended from the ceiling or support structures. It transports goods, parts, or materials along a predefined path using carriers, hooks, or trolleys. These systems are widely used in industries such as automotive, food processing, textiles, and logistics.

Key Components:

Track/Rail – The path along which the conveyor moves.

Trolleys/Carriers – Attachments that hold and transport items.

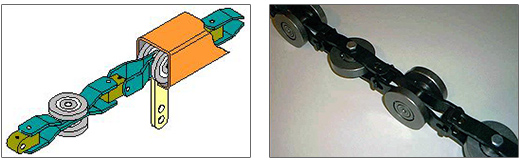

Drive System – Powers the movement (chain, belt, or motorized).

Controls & Automation – Manages speed, direction, and stops.

Types of Overhead Conveyors

Chain Conveyors – Durable and ideal for heavy loads (e.g., automotive assembly).

Monorail Systems – Single-track design for flexible routing.

Power & Free Conveyors – Allows independent stopping and movement of carriers.

Enclosed Track Conveyors – Protects the system from dust and debris.

Industry Spotlight: For businesses seeking high-quality, customizable overhead conveyors, CamelConvey offers robust solutions tailored to automotive, food, and industrial applications. Their systems emphasize energy efficiency, low maintenance, and smart automation – perfect for modern production lines.

Common Applications

Automotive Industry – Moving car parts through assembly lines.

Food Processing – Transporting meat, poultry, or packaged goods.

Warehousing – Sorting and distributing inventory.

Paint & Coating – Moving items through spray booths.

Overhead conveyor systems are a smart investment for industries looking to streamline operations. Companies like CamelConvey provide cutting-edge designs that integrate seamlessly with existing infrastructure while boosting productivity.