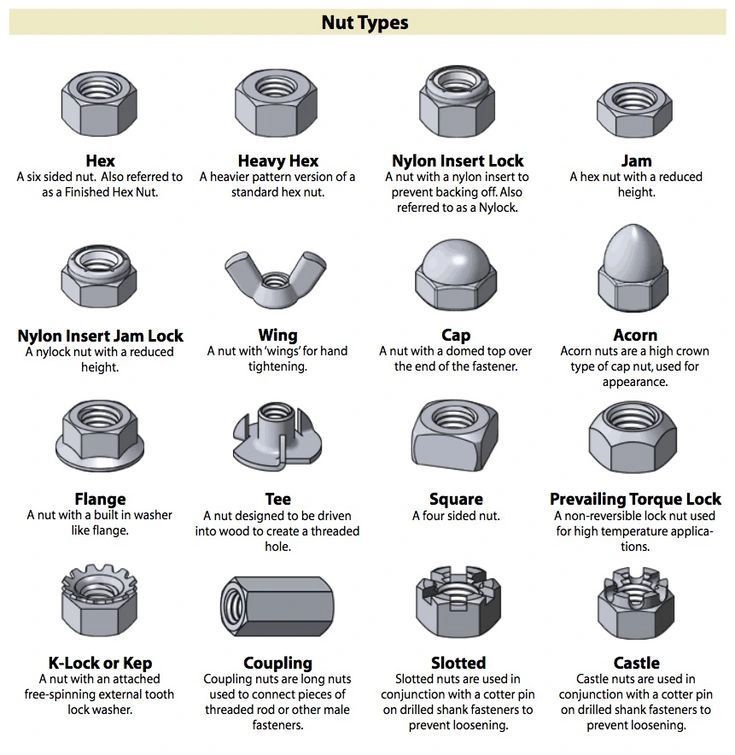

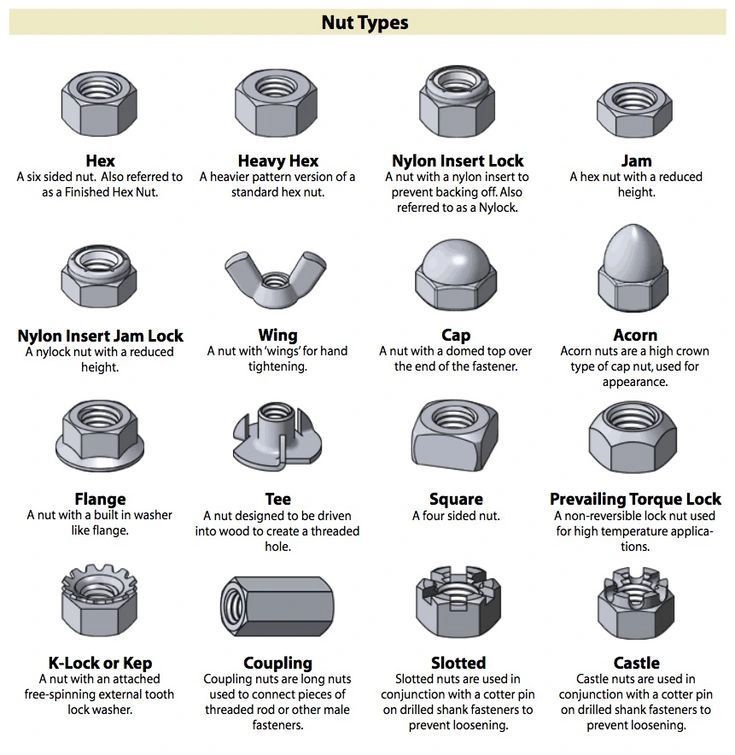

New Guide on Nut Types for Mechanical Engineering & Fastening Applications

- Share

- Issue Time

- Aug 20,2025

Summary

From securing assemblies to ensuring safety, nuts come in a wide variety of designs—each serving a specific purpose.

This resource covers hex nuts, heavy hex nuts, nylon insert lock nuts, wing nuts, and more, tailored to meet diverse industrial needs.

***Key Highlights***

Hex Nut: Standard six-sided nut, commonly used.

Heavy Hex Nut: Larger and stronger version of hex nut.

Nylon Insert Jam Lock: Reduced-height nylon lock nut.

Wing Nut: Easy hand tightening without tools.

Cap Nut: Domed top for safety and aesthetics.

Flange Nut: Built-in washer for load distribution.

Tee Nut: Driven into wood to create threads.

Prevailing Torque Lock Nut: Withstands vibration & high temps.

K-Lock / Kep Nut: Comes with a built-in lock washer.

Slotted Nut: Used with cotter pins for security.

Castle Nut: Similar to slotted, with extra slots for locking.

***Applications***

Ideal for machinery, automotive, structural, and industrial assemblies, these nut types enhance the reliability of conveyor and fastening systems.

Stay tuned for more CamelConvey's updates.