Light Type Enclosed Track Chain

- Share

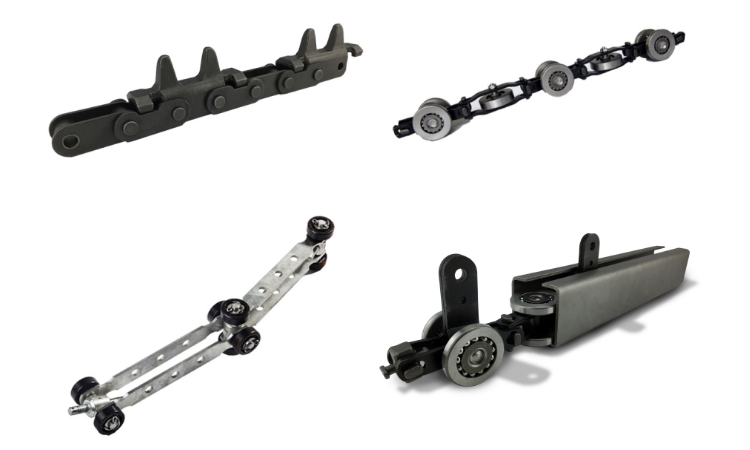

CamelConvey's componets in the light type enclosed track chain

There are three major ways to differentiate overhead conveyor systems: whether the track is open or enclosed; whether the system is powered electrically or manually; and whether the materials move synchronously or asynchronously. However, there can be many smaller differences between systems as they're often custom-made for specific applications.

CamelConvey offers 2 kinds of chains and trolley: a diverse range of conveyors tailored to optimize product handling during paint and other finishing operations. The selection of your conveyor system depends on factors such as item weight, size, shape, and the specific finishing process employed. Camelconvey provides specialized conveyor solutions for powder coating, wet spray, dip line, and E-coat applications, ensuring efficient and reliable performance throughout your production process.

Light Type Enclosed Track Chain Applications

CamelConvey's 5075 chain can reach 20kgs

CamelConvey overhead conveyors automate the handling process, ensuring a smooth and continuous flow of windows and doors through various stages of production, from assembly to finishing.

Labor Efficiency: With reduced reliance on manpower, our conveyors help lower labor costs and minimize the risk of human error.

Space Optimization: CamelConvey overhead conveyors make efficient use of available space by utilizing vertical areas, freeing up valuable floor space for other critical operations or equipment.

Custom Solutions: Our systems are customizable to meet the specific needs of your production line, whether it involves varying sizes or weights of windows and doors. We offer tailored configurations to ensure optimal performance and integration with existing processes.

CamelConvey's 7T chain can reach 35kgs

Electrocoating (E-coat finishing) and plating are essential metal finishing processes that fall under the broad category of electrophoretic deposition (EPD). EPD encompasses techniques like cathodic electrodeposition, anodic electrodeposition (anodizing), and electrophoretic coating and painting. These methods utilize electrical currents to deposit paint, adhering to the principle that opposites attract. Any particles capable of forming a stable suspension and carrying an electrical charge, such as polymers, pigments, dyes, ceramics, and metals, can be used in EPD. This versatile process can apply coatings to any electrically conductive surface. CamelConvey's plating includes Zinc plating, Black finished,Dacromet plating and so on.

CamelConvey's 8" enclosed can reach 60kgs

ABS painting, also known as Acrylonitrile Butadiene Styrene painting, involves the application of paint or coatings onto ABS plastic surfaces. ABS is a thermoplastic polymer known for its strong impact resistance, toughness, and ease of machining, making it a popular choice for a wide range of products, including automotive parts, consumer electronics, and household items. ABS painting is widely used in industries where aesthetic quality and durability are important. The painted ABS surfaces can withstand various environmental conditions, making them suitable for both indoor and outdoor applications. This painting process not only enhances the visual appeal of ABS plastic products but also provides additional protection against wear and tear.

CamelConvey's Service

We are committed to providing comprehensive services to meet your needs.

✔ Customization Services: Understanding the unique needs of our clients, we offer customization services to tailor solutions that meet specific operational requirements. ✔ We provide replacement services for chains from your previous brands: We offers high-quality overhead conveyor chain replacement services, compatible with various well-known conveyor systems. Whether for modernizing production lines or maintenance needs, we provide premium replacement chains to ensure optimal performance of your conveyor systems.

✔ Some products in stock: We maintain a comprehensive inventory of standard products, allowing for quick fulfillment of orders and ensuring consistency in quality. Contact us now.

CamelConvey's Light Type Enclosed Track Chain FAQ

What is the difference of Powered vs. free?

Powered overhead conveyors utilize an electric motor to drive the system and move materials along the track. This is a very energy efficient means of powering the system, having near-negligible energy consumption. Powered systems can also be automated, which can be especially useful in factories that already implement automation in other areas.

Manually operated — often referred to as ''free'' — overhead conveyors require manual labor to move materials along the track. Free conveyors are most effective for large, heavy materials, especially if a high level of precision is necessary.

Combined ''power and free'' overhead systems also exist, which combine a powered track and a free track. The powered track pulls trolleys along the free track, which can be started and stopped at certain points with a blade stop. These are preferred for high volume systems that need a high level of reliability and durability — such as those in the automotive industry.