Roller Turn Roller | Overhead Conveyor Components

- Model

- Roller Turn Roller

Item specifics

- Material

- Alloy Steel

- Heat Treatment

- Through Hardening

- Surface Treatment

- Natural

- Sample

- Available

Review

Description

Roller Turn Roller | Overhead Conveyor Component Description:

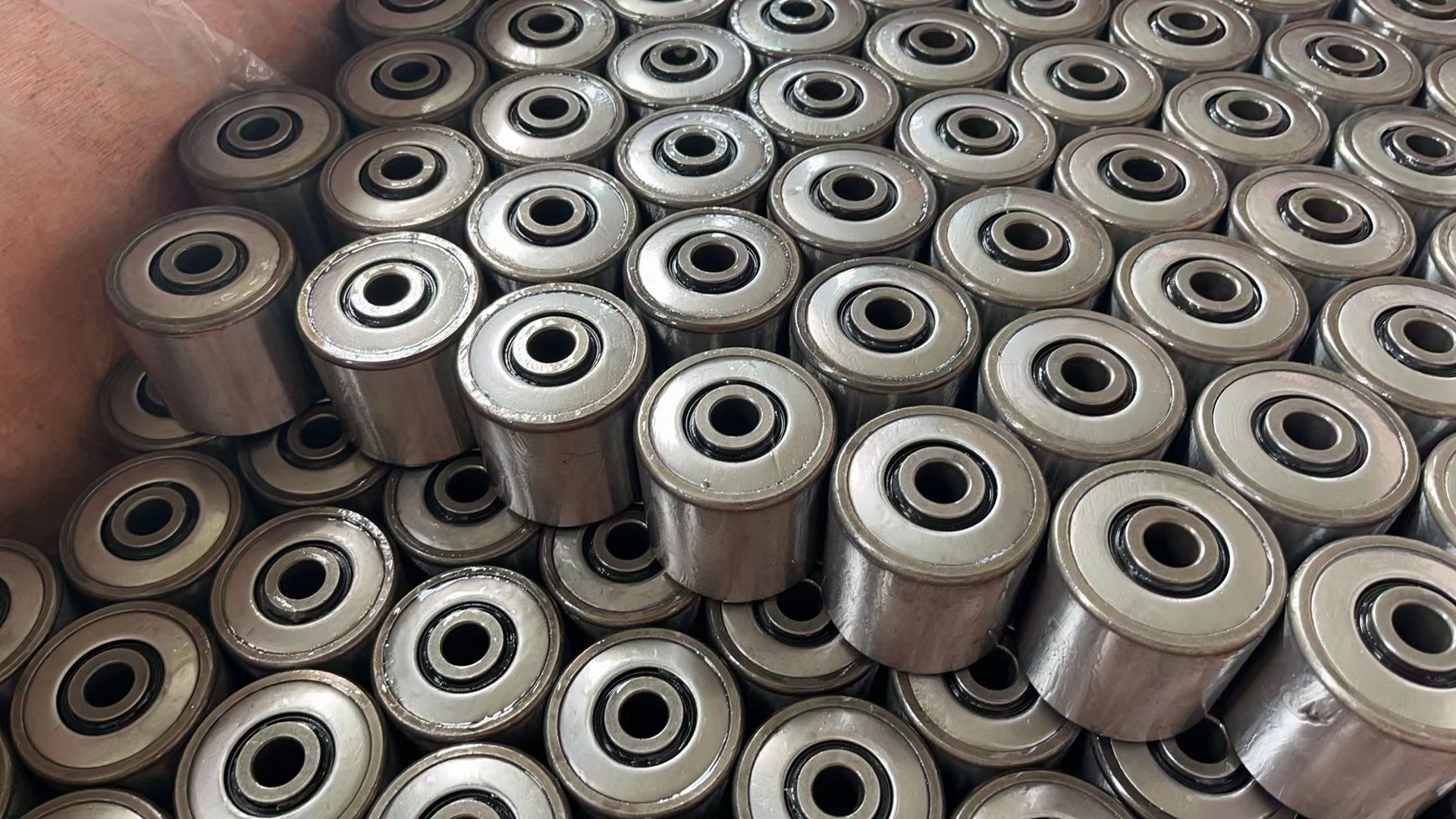

Roller Turn Roller | Overhead Conveyor Component Pictures:

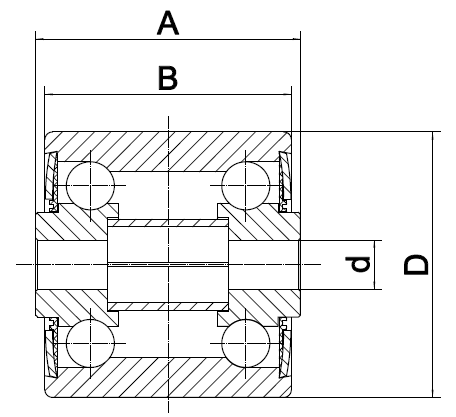

Roller Turn Roller | Overhead Conveyor Component Schematic Diagram:

Roller Turn Roller | Overhead Conveyor Component Specification:

Roller Number | Dimensions | Matched Chain | |||

A | B | D | d | ||

φ70X54 | 2.13" | 1.93" | 2.76" | 0.51" | X348 |

54mm | 49mm | 70mm | 13mm | ||

φ70X70 | 2.76" | 2.56" | 2.76" | 0.51" | X458、X678 |

70mm | 65mm | 70mm | 13mm | ||

Roller Turn Roller | Overhead Conveyor Component Overview:

Trustworthy CamelConvey

When assembling a roller turn roller, precision is key to ensure optimal performance in your overhead conveyor components. The process begins by installing high-quality steel balls, which facilitate smooth rotation. Next, the application of grease ensures long-lasting lubrication, reducing friction and wear. Finally, a protective dust cover is fitted to safeguard the internal mechanism from contaminants, enhancing the durability and reliability of the overhead conveyor parts. This meticulous assembly process is crucial for robust chain parts for overhead conveyor systems and the efficiency of overhead I beam conveyor components. Utilizing a conveyor chain with special attachments factory can further optimize your system's performance and longevity.

Looking for top-notch conveyor solutions? Trust CamelConvey, a leading manufacturer with over 30 years of experience. At CamelConvey, we are passionate about innovation and excellence. With a comprehensive product development and customer service system, we strive to offer the highest quality conveyor chains from China to customers worldwide.