698 Drop Forged Rivetless Chain | 698 Chain

- Model

- X698 Chain

Item specifics

- Material

- Alloy Steel / Stainless Steel

- Heat Treatment

- Through Hardening

- Surface Treatment

- None

- Sample

- Available

Review

Description

698 Drop Forged Rivetless Chain | 698 Chain Description:

The 698 Drop Forged Rivetless Chain, also known as the X698 chain, is a high-performance and heavy-duty conveyor chain designed for demanding industrial applications. This chain is meticulously engineered for robustness, featuring a simple detachable construction, which allows for quick assembly and easy repairs, minimizing downtime. Its loose link design and shaped inner bars enable significant lateral flexibility, making it ideal for use in overhead carousels and similar equipment where adaptability is crucial.

One of the standout features of the 698 chain is its self-cleaning design, which enhances its efficiency and reduces maintenance needs, making it particularly suitable for environments where debris and buildup could otherwise cause operational challenges. This self-cleaning ability is especially valuable in applications such as drag chains in swarf conveyors, where debris removal is essential for maintaining consistent performance and preventing blockages.

Manufactured by CamelConvey, a leading name in conveyor chain solutions, the X698 chain is available with a variety of attachments and external rollers, which can be customized to suit specific operational needs. Additionally, CamelConvey provides sprockets that are perfectly matched to the chains in their product line, ensuring seamless integration and optimal performance across the entire conveyor system.

The X698 chain is engineered with particular attention to the needs of the sugar industry, where it plays a vital role in the conveying and processing of sugar. In such demanding environments, the chain's increased flexibility and transverse pitch strength ensure superior operational performance, even under the strain of heavy loads, temperature fluctuations, and abrasive conditions. This makes the 698 chain an ideal choice for industries such as sugar processing, where the chain must endure heavy-duty cycles while maintaining reliable performance.

As a trusted Sugar Mill Chain Supplier, CamelConvey offers tailored solutions for Drop Forged Sugar Mill Conveyor Chains, allowing for customization to meet the unique demands of your conveying systems. Whether you're looking for standard or specialized solutions, the X698 chain provides the perfect combination of durability, flexibility, and efficiency, ensuring reliability and high-performance results in even the most challenging industrial environments.

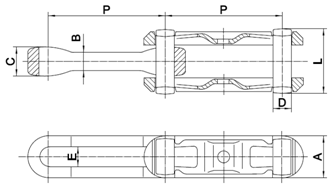

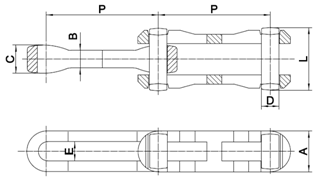

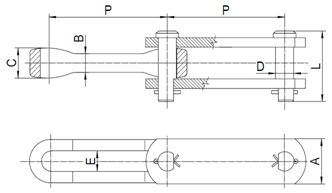

698 Drop Forged Rivetless Chain | 698 Chain Schematic Pictures:

698 Drop Forged Rivetless Chain | 698 Chain Schematic Diagram:

X-Type

Regular-Type

S-Type

698 Drop Forged Rivetless Chain | 698 Chain Dimensions:

Chain NO. | Normal Pitch | Actual Pitch | Pin Diameter | Pin Length | Other Dimensions | Ultimate Tensile Strength | |||

P | D | L | A | B | C | E | Q | ||

X698 | 6" | 6.03" | 1.126" | 3.74" | 2.54" | 1" | 1.54" | 1.26" | 114750lbs |

152.4mm | 153.2mm | 28.6mm | 95mm | 64.5mm | 25.4mm | 39mm | 32mm | 510KN | |