Drop Forged Link Chain | Agricultural Conveyor Chain

- Model

- Drop Forged Link Chain

Item specifics

- Material

- 40Cr

- Heat Treatment

- Through Hardening

- Surface Treatment

- None

- Sample

- Available

Review

Description

Drop Forged Link Chain | Agricultural Conveyor Chain Description:

The Importance of Drop Forged Link Chains in Industrial Applications

When it comes to heavy-duty conveyor systems, the durability and reliability of components are crucial to seamless operations. A well-engineered Drop Forged Link Chain stands out as a fundamental part of such systems, offering unmatched strength and longevity. Whether used in mining, construction, or manufacturing industries, understanding the significance of these chains and their optimal applications is essential.

Applications in Industry

● Mining Operations: The drop forged chain is essential for transporting raw materials efficiently and safely. These chains withstand the abrasive and heavy loads commonly encountered in mining.

● Manufacturing: They are a preferred choice for drag chain conveyor components, ensuring smooth and continuous movement of materials.

● Conveyor Systems: Many conveyor chain manufacturers rely on these chains to deliver performance that minimizes operational interruptions.

Why Choose CamelConvey Drop Forged Chains for Drag Conveyor Systems?

When considering heavy duty conveyor, the use of drop forged components ensures that materials are transported with maximum efficiency. Their robust construction makes them ideal for handling heavy, abrasive, or bulk materials in a variety of industrial processes. Components like the P142 chain are specifically tailored for these systems, providing the durability required to maintain operation under challenging conditions.

Selecting the Right Manufacturer

Choosing the right conveyor chain manufacturer is as important as selecting the right type of chain. A reputable manufacturer will provide high-quality components that adhere to rigorous industry standards, ensuring reliability and optimal performance. For those in need of customized solutions or specialty components, selecting an experienced supplier is key to maintaining system efficiency.

CamelConvey – Your Trusted Conveyor Chain Manufacturer

For businesses seeking reliable drop forged link chains and related agricultural conveyor chain, Camelconvey is a top choice. They are known for producing high-quality, durable chains that meet the most demanding industry standards. With Camelconvey, customers benefit from products that offer longevity, efficiency, and superior performance in even the harshest industrial environments.

Drop Forged Link Chain | Agricultural Conveyor Chain Pictures:

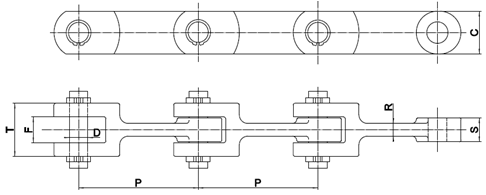

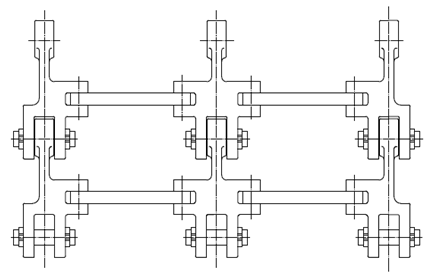

Drop Forged Link Chain | Agricultural Conveyor Chain Schematic Diagram:

Single Link

Double Link

Triple Link

Drop Forged Link Chain | Agricultural Conveyor Chain Specification:

Chain NO. | Pitch | Pin Diameter | Other Dimensions | Ultimate Tensile Strength | |||||

P | D | C | T | F | R | S | Q (20MnCr5) | Q (42CrMo4) | |

10160 | 4" | 0.55" | 1.42” | 0.94" | 0.39" | 0.235" | 0.35” | 24700lbs | 47200lbs |

101.6mm | 14mm | 36mm | 24mm | 10mm | 6mm | 9mm | 110KN | 210KN | |

10160R | 4" | 0.55" | 1.42" | 1.18" | 0.53" | 0.315" | 0.51" | 40500lbs | 74200lbs |

101.6mm | 14mm | 36mm | 30mm | 13.5mm | 8mm | 13mm | 180KN | 330KN | |

12514 | 4.92" | 0.63" | 1.42" | 1.18" | 0.63" | 0.39" | 0.59" | 36600lbs | 65200lbs |

125mm | 16mm | 36mm | 30mm | 16mm | 10mm | 15mm | 163KN | 290KN | |

14218 | 5.59" | 0.98" | 1.97" | 1.65" | 0.81" | 0.47" | 0.75" | 65200lbs | 123700lbs |

142mm | 25mm | 50mm | 42mm | 20.5mm | 12mm | 19mm | 290KN | 550KN | |

14226 | 5.59" | 0.98" | 1.97" | 2.44" | 1.18" | 0.63" | 1.12" | 99000lbs | 177700lbs |

142mm | 25mm | 50mm | 62mm | 30mm | 16mm | 28.5mm | 440KN | 790KN | |

16025 | 6.30" | 0.98" | 1.97" | 1.97" | 1.63" | 0.55" | 0.98" | 83200lbs | 147300lbs |

160mm | 25mm | 50mm | 50mm | 27mm | 14mm | 25mm | 370KN | 655KN | |

20028 | 7.87" | 1.18" | 2.36" | 2.60" | 1.22" | 0.79" | 1.18" | 112500lbs | 202500lbs |

200mm | 30mm | 60mm | 66mm | 31mm | 20mm | 30mm | 500KN | 900KN | |

Overview:

Trustworthy CamelConvey

CamelConvey Drop Forged Link Chain is designed through a precision forging process, which ensures that each link is robust and capable of handling substantial loads. The forging process improves the structural integrity of the metal, making it highly resistant to stress and wear, perfect for high-intensity applications like those found in drag conveyor chains.

Discover how CamelConvey's exceptional forged chains can enhance your operations. Contact us today to learn more about our custom solutions and see why we are a leader in the conveyor chain manufacturing industry.