Pin for X348 X458 X678 Chain | Overhead Conveyor Components

- Model

- Pin for Chain

Item specifics

- Material

- 40Cr

- Sample

- Available

Review

Description

Pin for X348 X458 X678 chain | Conveyor components Description:

All CamelConvey drop forged rivetless chains are commonly used in overhead conveyor systems and automated material handing systems, it consists of outer link, inner link and pin.Especially the pin plays an important role.

Why CamelConvey conveyor chain is also called dorp forged rivetless chain?

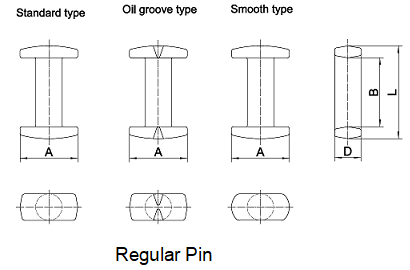

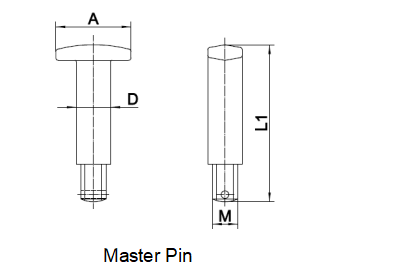

Because it is extremely easy to disassemble and assemble and it does not require any tool to do it.It’s the notches on the top and bottom of the pin that enable the oil to flow quickly down the pin to accurately reach critical lubrication points. Different chains with different pin diameters.X348 chain with dia.4/8", X458 chain with dia.5/8",X678 chain with dia.7/8", so X458 conveyor chain has a 4" pitch and pin size of 5/8", that is why we named them X348 chain, X458 chain and X678 chain. Besides, for the same diameter, CamelConvey also can provide oil groove pin, smooth pin and standard pin for cusomers' choices as I beam conveyor chain manufacturer.

Pin for X348 X458 X678 chain | Conveyor components Pictures:

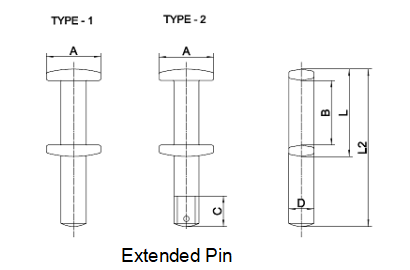

Pin for X348 X458 X678 chain | Conveyor components Schematic Diagram:

Pin for X348 X458 X678 chain | Conveyor components Specification:

Chain No. | Pitch | Pin Diameter | Pin Length | Other Dimensions | |||||

P | D | L | A | B | C | M | L1 | L2 | |

X678 | 6" | 0.874" | 3.03" | 1.89" | 2.26" | 1.14" | 0.63" | 3.86'' | 5.35'' |

152.4mm | 22.2mm | 77mm | 48mm | 57.5mm | 29mm | 16mm | 98mm | 136mm | |

X458 | 4'' | 0.625'' | 2.24'' | 1.26'' | 1.635'' | 0.98'' | 0.47'' | 3.19'' | 4.41'' |

101.6mm | 15.88mm | 57mm | 32mm | 41.5mm | 25mm | 12mm | 81mm | 112mm | |

X348 | 3'' | 0.5'' | 1.81'' | 0.98'' | 1.3'' | - | - | - | - |

76.2mm | 12.7mm | 46mm | 25mm | 33mm | - | - | - | - | |

Custom dimensions are also available.

Pin for X348 X458 X678 chain | Conveyor components Overview:

Trustworthy CamelConvey

In I-beam conveyors, drop-forged pins play a critical role in maintaining smooth and reliable operations. Over time, these components undergo significant stress and wear, and proper inspection is essential to avoid costly downtime or accidents. From the video, by following these best practices and maintaining thorough records, companies can significantly reduce the likelihood of unexpected pin failure, ensuring safe and efficient conveyor operation. Regular, proactive inspections not only extend the lifetime of the pins but also contribute to the overall safety and reliability of the conveyor system.